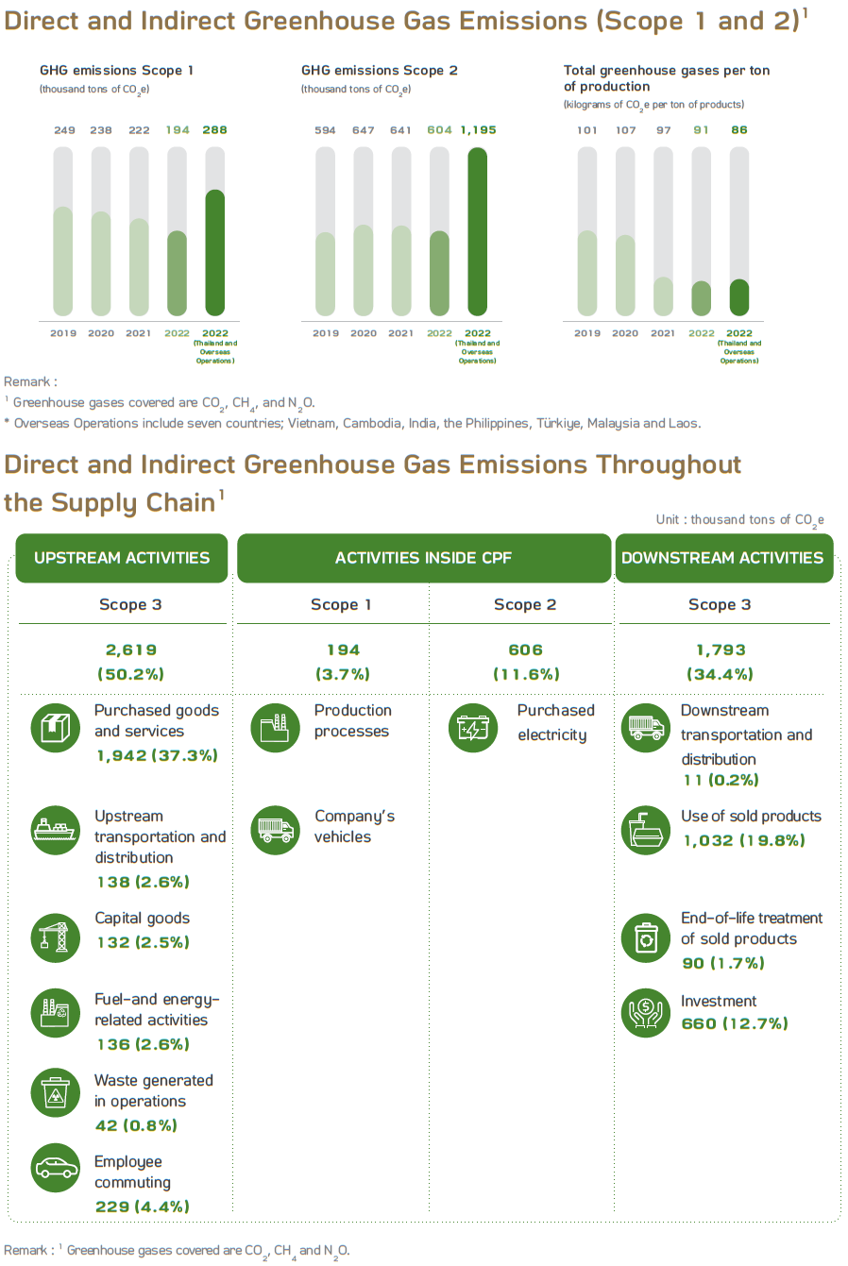

We promote energy efficiency, increase the use of renewable energy and support the management and valorization of waste/wastewater in our feed, farm-processing, and food business in order to reduce greenhouse gas emissions. At the same time, we also promote the increase in green areas in our operations to help sequester carbon dioxide. We, therefore, have set the targets to reduce direct and indirect greenhouse gas emissions per production unit by 25% by 2025, compared to those in the base year 2015.

High Efficient Manufacturing

CPF’s energy management planning includes a plant design, where production efficiency and resource use are considered in order to select machinery and equipment, as well as regular maintenance of machinery and equipment to reduce energy loss in the production process. CPF is committed to continuously improving energy efficiency in the production processes by implementing various projects including:

- Co-generation Power Plant Project;

- Improvement of Cooling and Air Conditioning Systems Project; and

- High Efficiency Lighting Equipment Replacement Project (LED Project).

Promoting Renewable Energy

- CPF set the target to phase out coal as fuel for Thailand operation in 2022 or “CPF Coal Free 2022” which has been accomplished in December 2022 (See Assurance Statement here), covering all 12 of the company's livestock feed mills, 2 aqua-feed mills and a duck-fowl feather processing plant. CPF plans to expand this success overseas in the next step.

- Biomass from waste materials including wood chips, sawdust, corncobs, etc., are used to substitute coal in powering boilers, reducing greenhouse gas emissions by more than 42,000 tons of carbon dioxide annually.

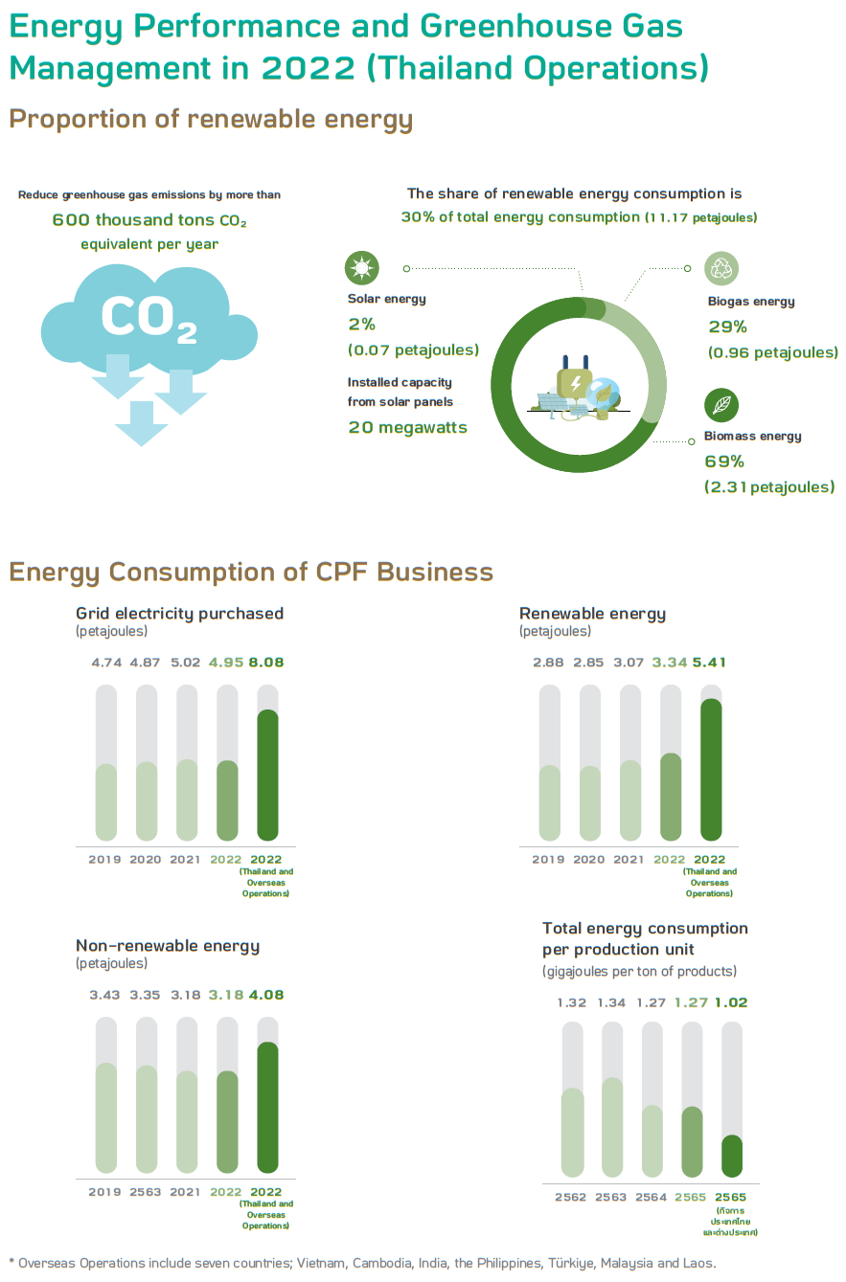

- Solar energy is used in feed mills, animal farms, food processing plants, food production plants, and distribution centers installed solar PV panels to generate electricity to be used in production processes. The total production capacity in 2022 is 20 MW. Moreover, CPF plans to complete more 60 solar rooftops, solar farms and floating solar sites by 2023, generating a total of 43 megawatts of solar power or equivalent to 62 million units of electricity per year. This green energy project will reduce greenhouse gas emissions by 26,000 tons CO2 per year or equivalent to planting 2.8 million trees per year.

- Electricity Generation from Biogas Project: we implement the “Green Farm” project in our own and contract farmers’ swine farms by transforming wastewater and swine manure into biogas through a wastewater treatment system. Biogas is a by-product that can be used to power the farms, replacing purchased electricity from external sources and help reduce greenhouse gas emissions. The success of the “Green Farm” Project in swine business has been further expanded to the layer business since 2017.

Success in 100% Coal Free Target in Thailand Operations

CPF is determined in environmental stewardship in accordance with our environmental strategy and target, thus initiated CPF Coal Free 2022 to terminate the coal utilization 100% across Thailand operations. The target was achieved recently in December 2022 with an expansion plan to overseas operations. This can be regarded as a crucial pilot in the shift towards CPF’s Net Zero future.

Since 2019, CPF has invested in upgrading steam production equipment originally powered by coal fuel to be compatible with biomass. This includes CP Feed Mill Bangna KM.21, Mahachai’s Aquaculture Feed Mill, Nong Kae's Aquaculture Feed Mill, and Samutprakan’s Manufacture of Chicken feather meal and Dry Duck feather Processing Plant. Clean energy from biomass, such as scrap wood chip and corn cob, was utilized in place of coal in steam production, resulting in over 42,000 tons carbon dioxide equivalent reduction annually. This represented a remarkable step in CPF’s journey towards Net-Zero and mitigate climate-related regulatory risks in the future.

To solidify our success, CPF appointed LRQA (Thailand) Limited as a third party to verify the result of our initiative based on internationally recognized standard for transparency. The assurance statement affirmed that CPF has terminated coal utilization in steam production since December 2022.

CEO of CPF receiving CPF Coal Free by the Year 2022 Assurance Statement from LRQA Verifier.

See Assurance Statement here

Climate-friendly Products

Environmentally Friendly Feed Innovation

Since 2017, CPF has developed an environmentally friendly swine feed that can reduce excess nitrogen from swine excretion by 20-30%. In 2020, we further developed layer chicken feed by balancing sources of protein together with the selection of suitable enzymes for animals at different ages, all of which increase digestive efficiency of animals. As a result, animals grow effectively and are healthy. At the same time, it reduces animal feed ingredients such as fishmeal and soybean meal that exceeds animal needs and thus is excreted. It also helps reduce odor caused by manure as well, nitrogen from layer chicken excretion was reduced by 12-13%.

Low-Carbon products

Examples of products certified with the Carbon Footprint Reduction Label by Thailand Greenhouse Gas Management Organization (Public Organization) or TGO, consisted broiler feeds, live broiler chickens, live ducks, fattening pigs, and fresh chicken meat, fresh duck meat and fresh pork meat products.

In 2022, all low-carbon products reduce GHG emissions by over

2,337,566 tons of CO2e

The amount of greenhouse gas (GHG) emissions reduction from low-carbon products is calculated from the weight of products receiving Carbon Footprint of Products (CFP) label Carbon Footprint Reduction (CFR) label from Thailand Greenhouse Gas Management Organization (TGO), multiplied with GHG reduction of each product, which is based on a comparison with Thailand’s average product carbon footprint or with the product carbon footprint in base year.

*Emission factor is referenced from TGO.

Supporting Mechanisms for GHG Emissions Reduction

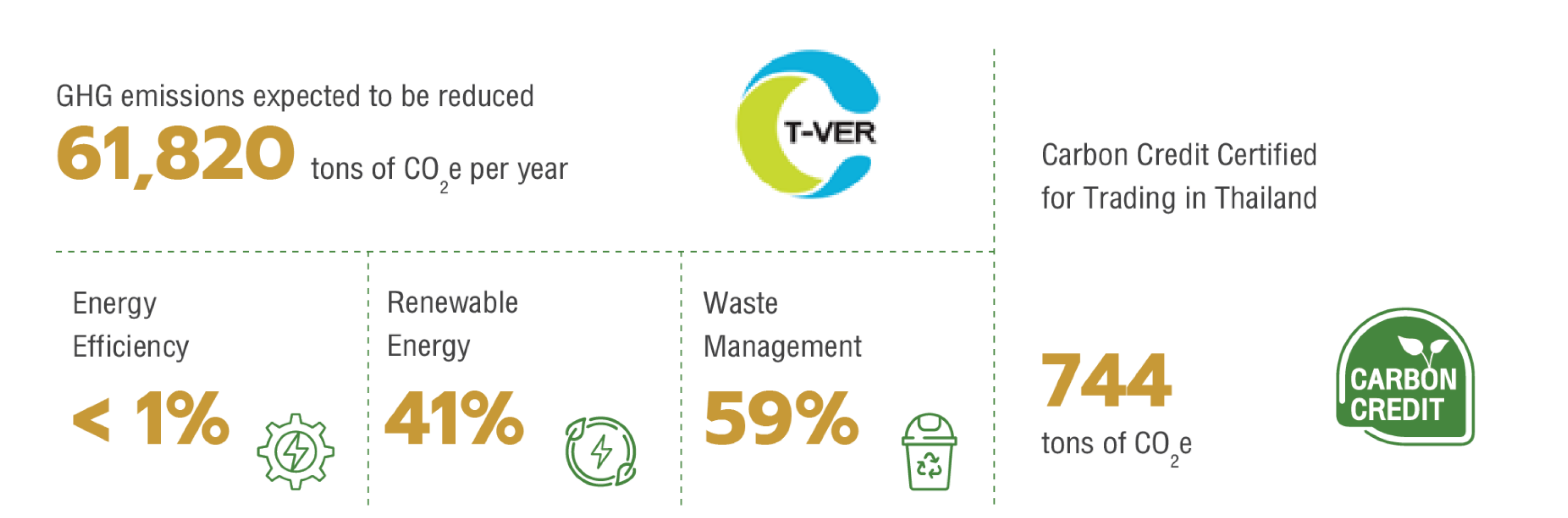

Energy consumption and waste management are major contributors to climate change. Therefore, CPF has implemented projects to increase energy efficiency, managed manure and wastewater, and promoted renewable energy, for instance, biodiesel, biogas and solar to continuously reduce GHG emissions. CPF has registered for Thailand Voluntary Emission Reduction Program (T-VER) with TGO. Details of the implementations are as follows:

Moreover, CPF has been awarded a certificate from TGO for the Low Emission Support Scheme (LESS) Project in the category of forestry and agriculture, for the CPF Rak Ni-Ves at Phraya Doen Thong Mountain Project, green area in farms and factories and renewable energy from solar energy project. Details are as follows:

Employee Capacity Building through “GHG Management: Carbon Footprint” Program

CPF organized an online training program “GHG Management: Carbon Footprint” with objectives to raise awareness in greenhouse gas (GHG) management or carbon footprint in agro-industrial business and promote understanding in principles importance and processes in carbon footprint assessment in line with CPF SHE&En Standard, in order to be applied across CPF operations.

The program covered current situation in GHG emissions, general knowledge on carbon footprint assessment and step-by-step carbon footprint assessment process.

The target audience included management and employees involved in CPF SHE&En Standard implementation. In 2022, two batches of this training program have enhanced the knowledge for 348 participants.

Cooperation in Climate Change Adaptation within the Supply Chain

CPF has applied a maize traceability system to trace back to planting plots to ensure that maize, a key raw material in the Company's animal feed production, originates from non-deforestation area. CPF has also implemented “Self-Sufficient Farmers, Sustainable Corn Projects” to raise awareness and understanding among maize farmers and improve agriculture which, in turn, increases productivity while reducing the impact on climate change, adjusts fertilization to suit the areas and growth of maize, promotes use of organic fertilizers instead of chemical fertilizer and growing of ground cover crops, and reduces tilling or stubble burning. In 2022, there are 462 smallholder farmers participating in the project, representing 25,054 rai (4,008 hectares) of planting area.