Recognizing its significant role in protecting biodiversity and solving climate change, one of the causes of which is the decrease in forest areas across the world, which are animal habitats, in order to use lands for agricultural activities and animal raising, CPF therefore has proclaimed its Biodiversity and Zero Deforestation Commitment and set targets for purchasing agricultural direct raw materials, namely corn, fishmeal, palm oil, soybean and cassava. 100 percent of CPF's global supply must be traceable and come from deforestation-free areas within 2030, which is an extension of the targets in 2020.

In addition, CPF has identified the critical raw materials which are at risk of forest encroachment, namely corn, soybean, palm oil and cassava. CPF set up guidelines for deforestation-free agricultural areas verification to ensure that each direct raw material does not come from encroachment areas or areas of deforestation.

Procurement of Corn

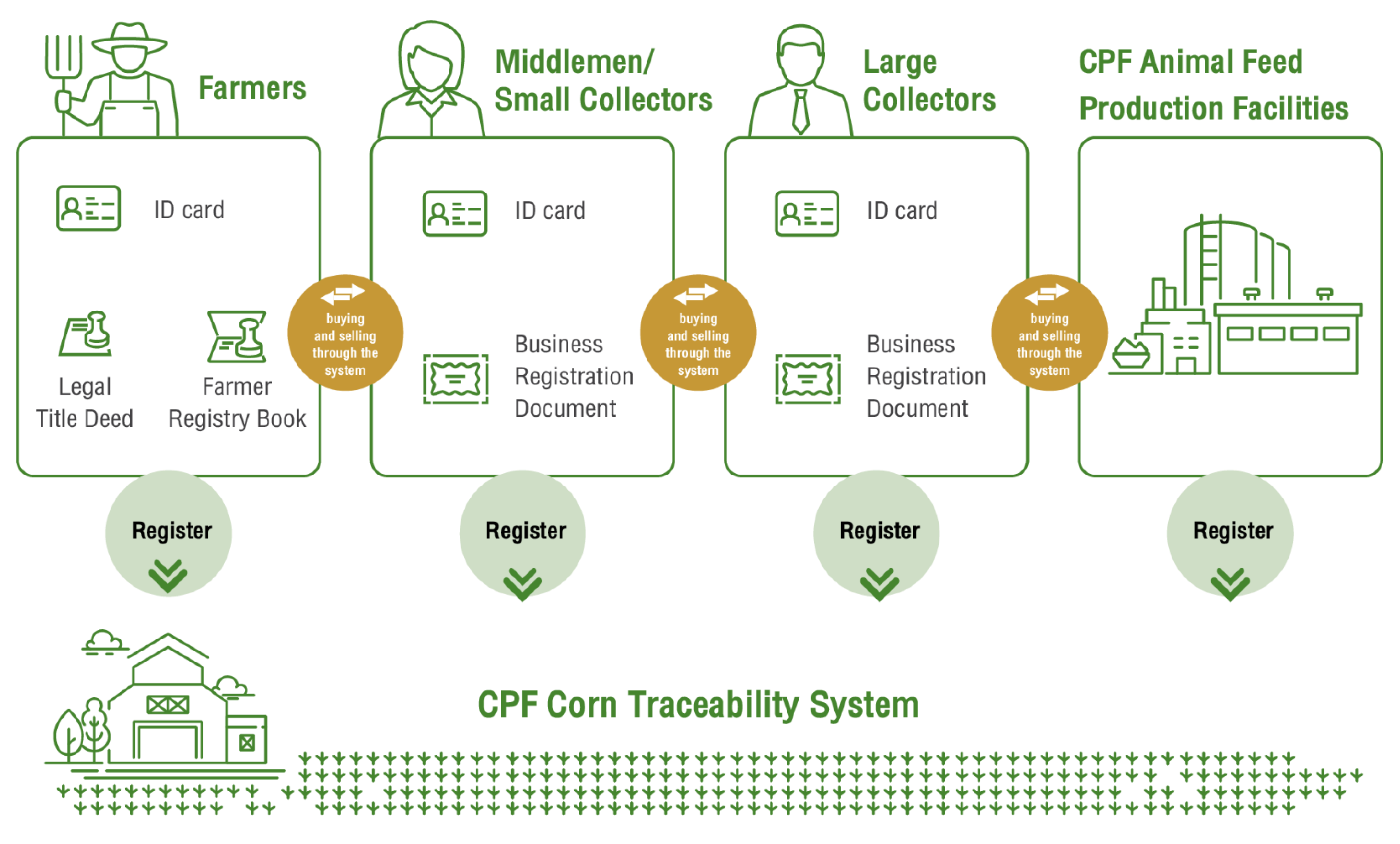

CPF has used the Corn Traceability System to verify that corn imported to distribute to its animal feed mills are sourced from farmland without burning stubble after harvesting, and can be traced back to plantation areas.

The Supplier Registration on Traceability Program is a gateway for CPF to track its farmers’ identification, land used rights and agricultural activities through online communication platform to ensure the traceability of CPF agricultural raw materials and deforestation free commitment.

The procedure to implement traceability program consists of

- Communicate with the farmers through face-to-face on the traceability approach

- Educate and introduce the digital traceability system to the farmers by introducing this manual which requires farmers to register and provide their identification information, land rights and their farming location to keep record of the identification of the farmers and to ensure that the farming areas are in the regulated zones as per Thailand Agricultural Land Reform Office and not encroach the forest area.

- The Company will conduct due diligence on the farmers identification and documents. Those who pass the verification process will be approved and can start using the system.

- Once the farmers are approved, they will be in the traceability programs ensuring traceable agricultural raw materials and deforestation free. The farmers can enjoy some perks within the system, such as, real time price updates on certain agricultural products and real time weather updates based on the traceability system platform.

See details in Supplier Registration and Engagement Manual

In 2022, 100 percent of corn in Thailand operations were traceable to plantation areas through the Corn Traceability System. CPF is also enhancing data management in the corn traceability system by linking it to CPF feed mills’ production processes. In this regard, a blockchain technology is used to improve the speed of agricultural raw material traceability to plantation areas, and to ensure customers that raw materials are from responsible sources / sustainable sources / zero deforestation and reflect “Innovative Organization with Technology” in all CPF’s business processes.

Furthermore, within 2030, CPF sets a target to source 100 percent of corn used in CPF's global operations must be traceable to plantation with the Corn Traceability System. At present, the Company has expanded the work scope to key overseas operations, which are Laos, Cambodia, Vietnam, Malaysia, India, and the Philippines operations. 51.80 percent of the total quantity of corn in CPF’s global operations were traceable to plantation.

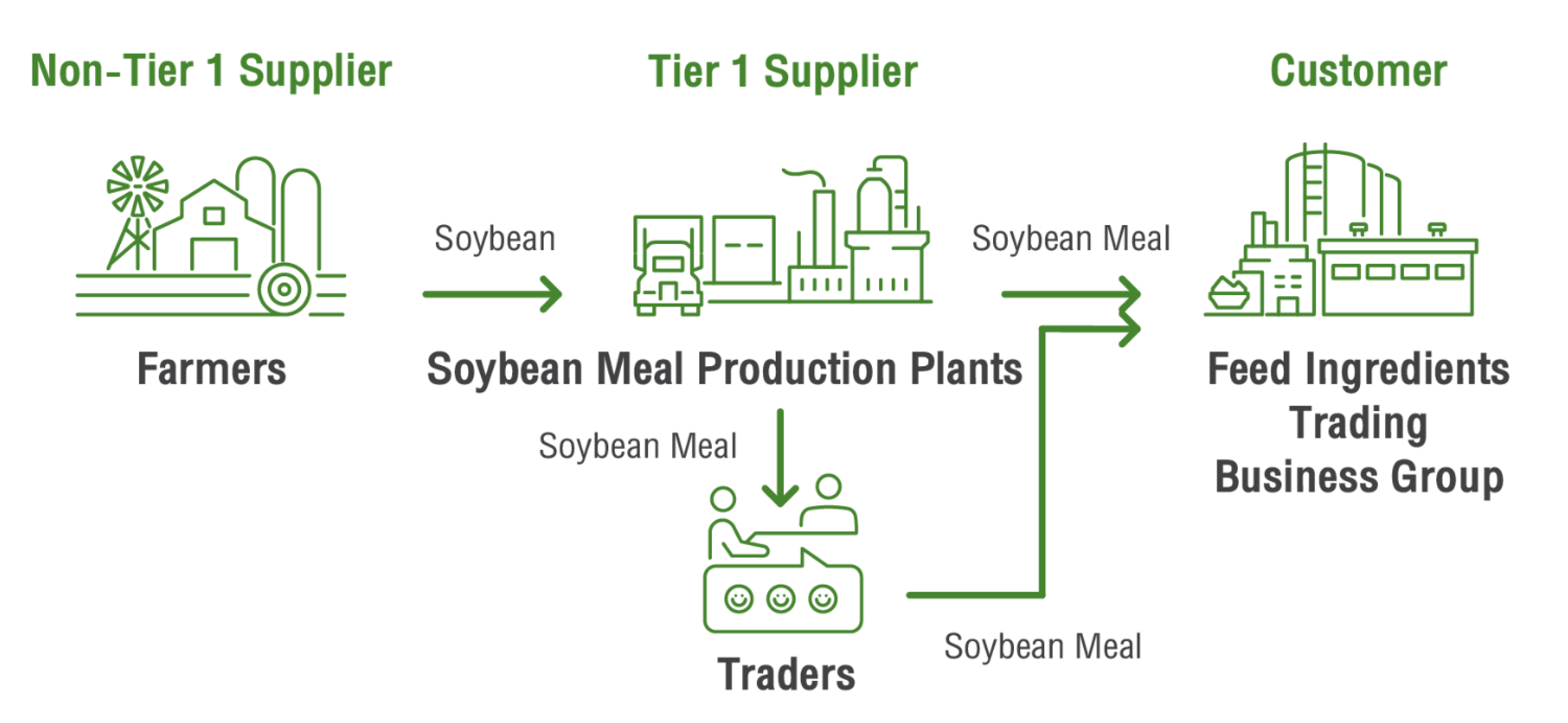

Procurement of Soybean Meal

CPF collected information on the origins of soybean, a feedstock of soybean meal, to identify any risk from procuring products which may come from forest encroachment areas, and researched guidelines for responsible sourcing of soybean meal. The information obtained was applied and adapted to match the business strategies and goals setting on purchasing agricultural raw materials that are from zero deforestation areas.

CPF sets a target to source 100 percent of soybean meal that are traceable to production location, countries and states of origin, and also targets to source soybean meal that is from deforestation-free areas by 2030.

In 2022, the Company found that around 46.34 percent of soybean meal that had been procured for its worldwide operations was traceable to the countries and states of origin. CPF is working with the group of soybean meal suppliers to implement the verification data and documents for procurement of soybean meal.

Procurement of Palm Oil

CPF has procured good quality palm oil as raw material for animal feed and food businesses, which must be systematically traceable or meets international standards such as the Roundtable on Sustainable Palm Oil (RSPO).

Within 2030, CPF targets to expand its practices to source 100 percent of palm oil that is traceable or sources from certified palm oil mill with an international sustainable standard, such as, the Roundtable on Sustainable Palm Oil (RSPO) to the overseas operations.

In 2022, the Company has been procuring according to the target to source palm oil that are systematically traceable as planned for the feed business and food business as follows:

- For feed business in Thailand operations, 100 percent of palm oil was traceable to the production plants.

- For food business in Thailand operations, around 79 percent of palm oil was certified by RSPO.

Procurement of Fishmeal

CPF has procured fishmeal as one of the raw materials used in animal feed production, and it is the only raw material that links the Company’s business to the fisheries which is found to be at risk of labour practices and marine biodiversity loss. As a leading integrated agro-industrial and food business, the Company is committed to supporting sustainable sourcing of fishmeal in accordance with the “CPF Fishmeal Sourcing Restrictions” which stipulates sourcing guidelines from two sources, namely:

- By-products derived from aquatic processing plants such as the surimi factory, the canned tuna factory, and the fish ball factory that have been certified by MarinTrust Standard or MarinTrust Improver Programme which is a standard that complies with Code of Conduct for Responsible Fisheries of the Food and Agriculture Organization of the United Nations (FAO), or must not be by-products from species at risk of extinction as listed in the International Union for Conservation of Nature (IUCN)’s Red List of Threatened Species which is internationally recognized, or by-products that can be traced back by third party.

- By-catch with internationally recognized sustainability and traceability standard; MarinTrust Standard which is certified by the International Fishmeal and Fish Oil Organization or by-catch that can be inspected by inspection mechanism supported by law, which consists of various sectors such as officials or representatives from the Department of Fisheries, entrepreneurs, concerned communities, consumers and technocrats.

In 2022, the Company has been procuring fishmeal for aqua animal feed production in accordance with the “CPF Fishmeal Sourcing Restrictions”, and was able to report its performance for Thailand and Overseas operations as follows:

- For feed business in Thailand operations: 100 percent of fishmeal is made from by-products of processing plants that comply with the “CPF Fishmeal Sourcing Restrictions”.

- For feed business in Vietnam operations:

56.91 percent of fishmeal is made from by-products of processing plants that comply with the “CPF Fishmeal Sourcing Restrictions”. Examples of fish species can be seen here.

56.91 percent of fishmeal is made from by-products of processing plants that comply with the “CPF Fishmeal Sourcing Restrictions”. Examples of fish species can be seen here. 12.93 percent of fishmeal is made from by-catch that comply with the “CPF Fishmeal Sourcing Restrictions”.

12.93 percent of fishmeal is made from by-catch that comply with the “CPF Fishmeal Sourcing Restrictions”.- For feed business in other countries of operations: 56.61 percent of fishmeal is made from by-products and by-catch that comply with the “CPF Fishmeal Sourcing Restrictions”.

Performance