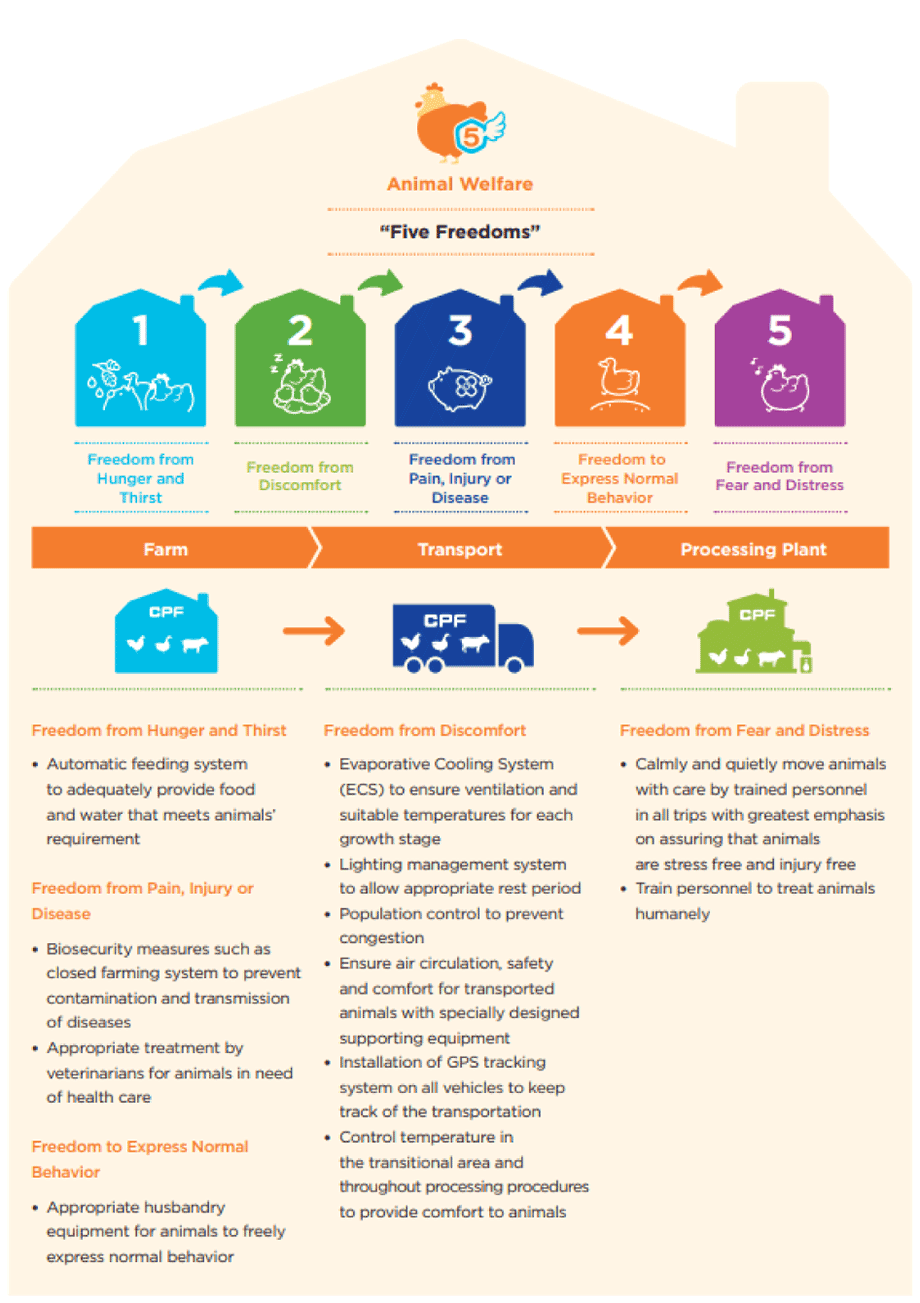

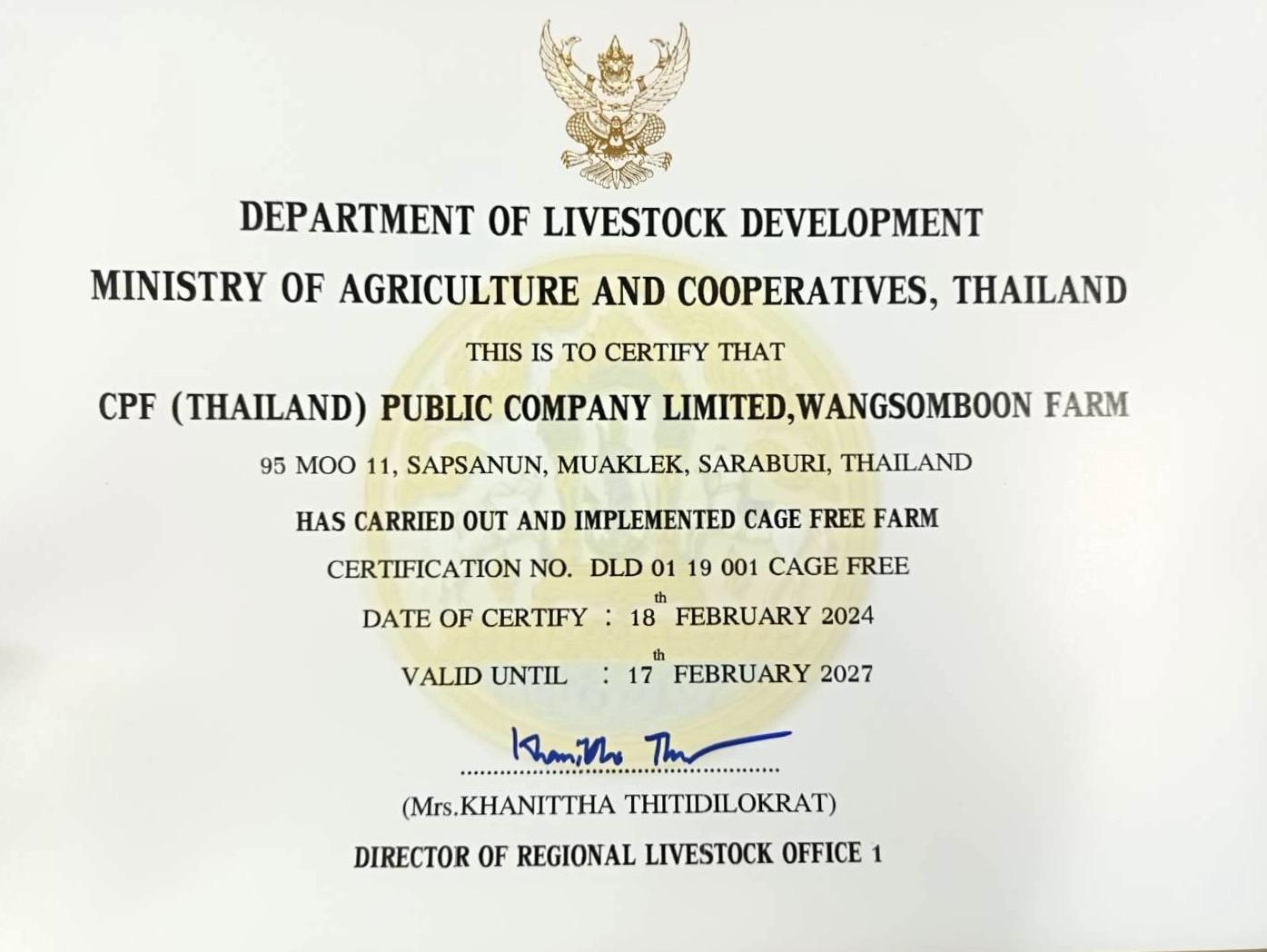

The Company emphasizes raising all of our animals on a basis of good animal welfare practices without constraining them in limited small housing in order to provide them with the freedom to fully express natural behaviors. We raise fattening pigs, chicken breeders, broilers, duck breeders and ducks in all operating countries in a group housing system to provide enough space for them to express their natural behaviors. For swine breeder farming, we have transitioned our pregnant breeder sow farming towards a group housing system since 2000. Our target is to transition 100 percent of our own and contracted farms in every operating country to a group housing system by 2028. For layer farming, we are committed to transitioning from a conventional cage system to a cage-free system which we have already piloted on the Wang Somboon farm in Saraburi Province in 2019.

Furthermore, to comply with animal welfare principles, the Company has a clear policy on limited transportation time for all live animal transportation. 100 percent of live animal transportation must be completed within eight hours, and the vehicles must be installed with a proper temperature control and ventilation system so that animals are comfortable throughout the journey. To achieve this, we specified that farming areas must be located close to slaughter houses. However, the Company has contingency plans when the terrain is unfavorable, leading to transporting which takes longer than eight hours, we will apply a stress easing measure by requiring that the vehicles must stop every two hours to provide water for and check on animals. Moreover, unloading animal practices must be in line with animal welfare principles and must be done as gently as possible. The unloading area must be in proper ventilation and with appropriate temperature so that animals are relaxed and calm.

|

Average time to transport live animals* (hours) |

Maximum time to transport live animals* (hours) |

|||

|---|---|---|---|---|

| 2023 | 2024 | 2023 | 2024 | |

| 1.8 | 1.8 | 6.5 | 3.1 | |

| 3.2 | 3.0 | 7.0 | 5.3 | |

| 1.1 | 2.0 | 6.0 | 3.5 | |

| 3.7 | 4.0 | 7.8 | 8.3 | |

| 2.7 | 2.3 | 5.0 | 5.2 | |

- Use electrical waterbath stunning

-

Use carbon dioxide or low voltage electric current

- Use ice

- Use electric current

(Partial)

(Partial)

| Enhancement of Physical Environment (%) | ||||||

|---|---|---|---|---|---|---|

| Sow | Nursery Pig | Wean-to-Finish Pig | ||||

| 2022 | 61.13 | 100* | 100 | 44.02 | 97.31 | 71.09 |

| 2023 | 88.00 | 100* | 83.34 | 41.68 | 60.64 | 90.18 |

| 2024 | 61.50 | 100* | 100 | 56.10 | 40.10 | 89.80 |

|

|

|

|

|

|---|---|---|---|

Paddy husk bale for climbing |

Perch for hanging |

Water troughs for placing their heads |

Chewing objects e.g. strings and Napier grass |

Pecking objects |

Flooring materials for scratching and pecking |

Collecting samples from saliva |

|

Places for laying eggs |

|

Stakeholder |

Dissemination method |

|---|---|

|

CPF |

Seminars, meetings, farm visits, trainings, and on-site coaching |

|

Farmers under the Contract Farming Project |

Seminars, meetings, farm visits, and on-site coaching |

|

External Farmers |

Seminars and farm visits |

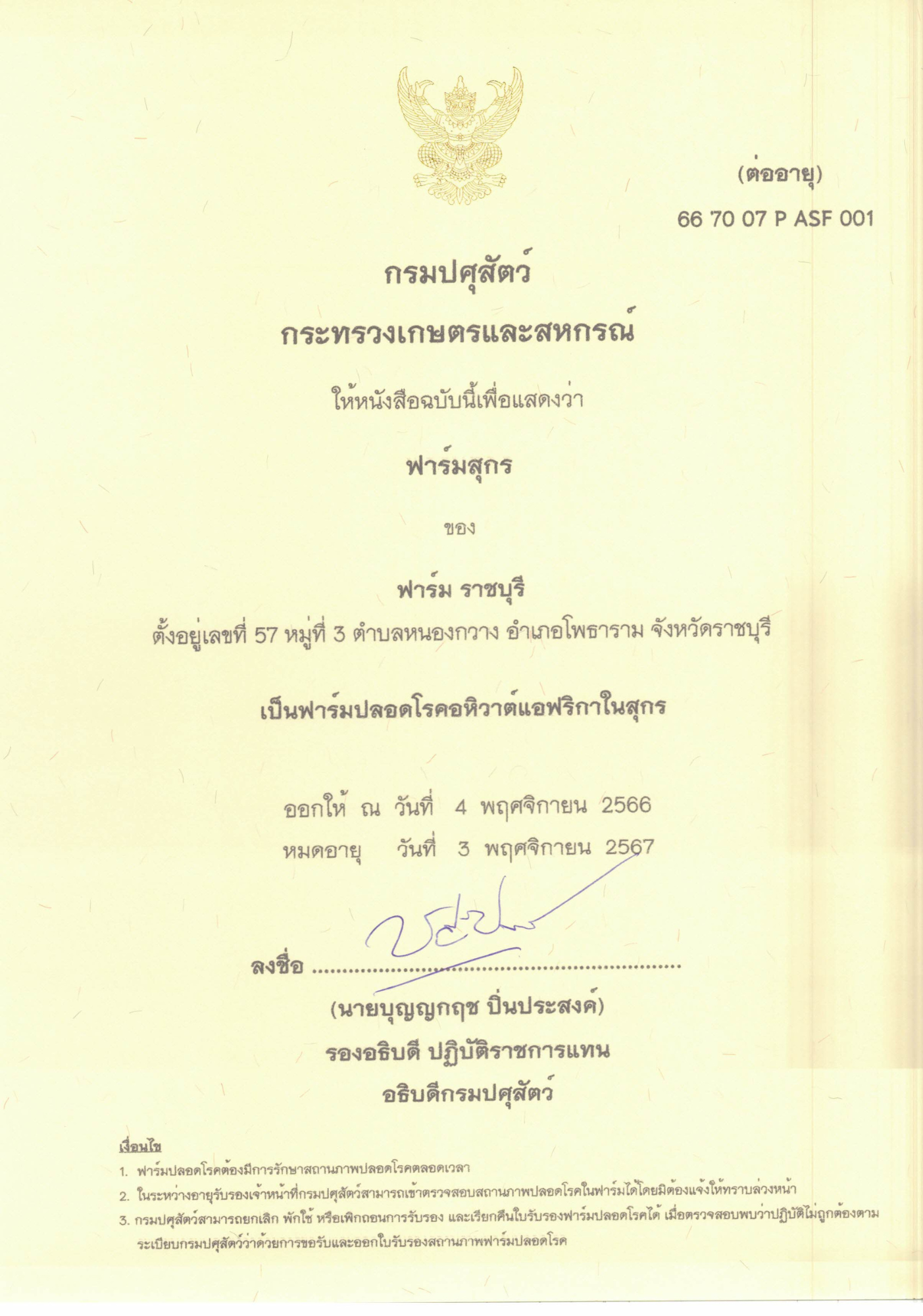

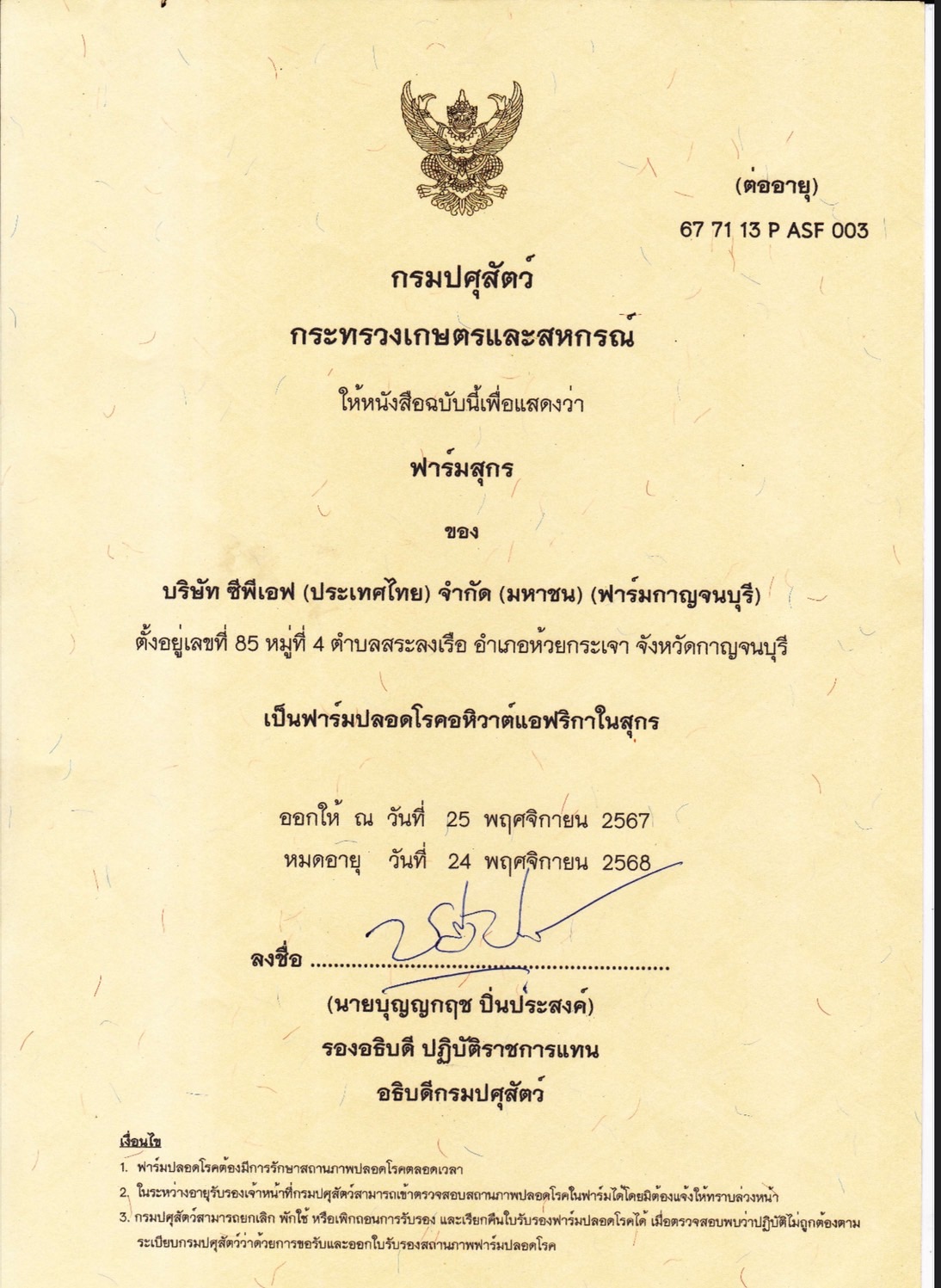

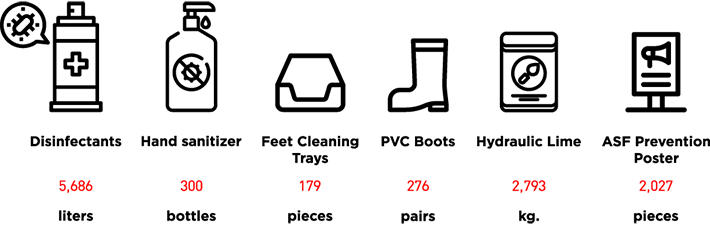

We supported construction of a cleaning and disinfection of livestock transportation vehicle center on the border of Chiang Rai and Mukdahan provinces worth 4 million Baht.

We organized a seminar to disseminate knowledge on the topic of “Be Aware to Prevent the ASF” to 7,262 farmers under the Contract Farming Project in 38 provinces worth 2.2 million Baht.

We provided on-site knowledge sharing and promotion of preventative measures against the ASF for 2,156 small holder farmers within five kilometers of farm radius across 58 provinces, and supplied appropriate prevention equipment against the ASF worth 2.5 million Baht.

The Company’s operations in India held a training session on poultry welfare for broiler farming with relevant farming personnel from southern, eastern and western regions of India. There was a total of 30 attendees in the training session on 3 July 2019 which was organized by PWO from Thailand.

The Company’s operations in Thailand have piloted installing Pekino for ducks designed to have a funnel shape similar to duck necks which mimics their natural behavior when drinking water by submerging their heads in the water. This enables ducks to be in good health and be strong, facilitates them in fully submerging their heads in the water, and allows them to keep water in their mouth and flap water to groom naturally, simulating the expression of their natural behaviors.

The Company’s operations in Malaysia have piloted the first closed cage-free housing system for layers, allowing them to move freely within the area, and enabling them to feel relaxed and improve their health.

The Company’s operations in Vietnam have developed removable pen barriers in fattening pig housing, replacing the previous separate enclosed system. This enables them to express their natural behaviors, and move freely, from the first to the last pens, resulting in reduction of the stress level.

The Company adheres to Five Freedom Principles and our farms have no slatted flooring.