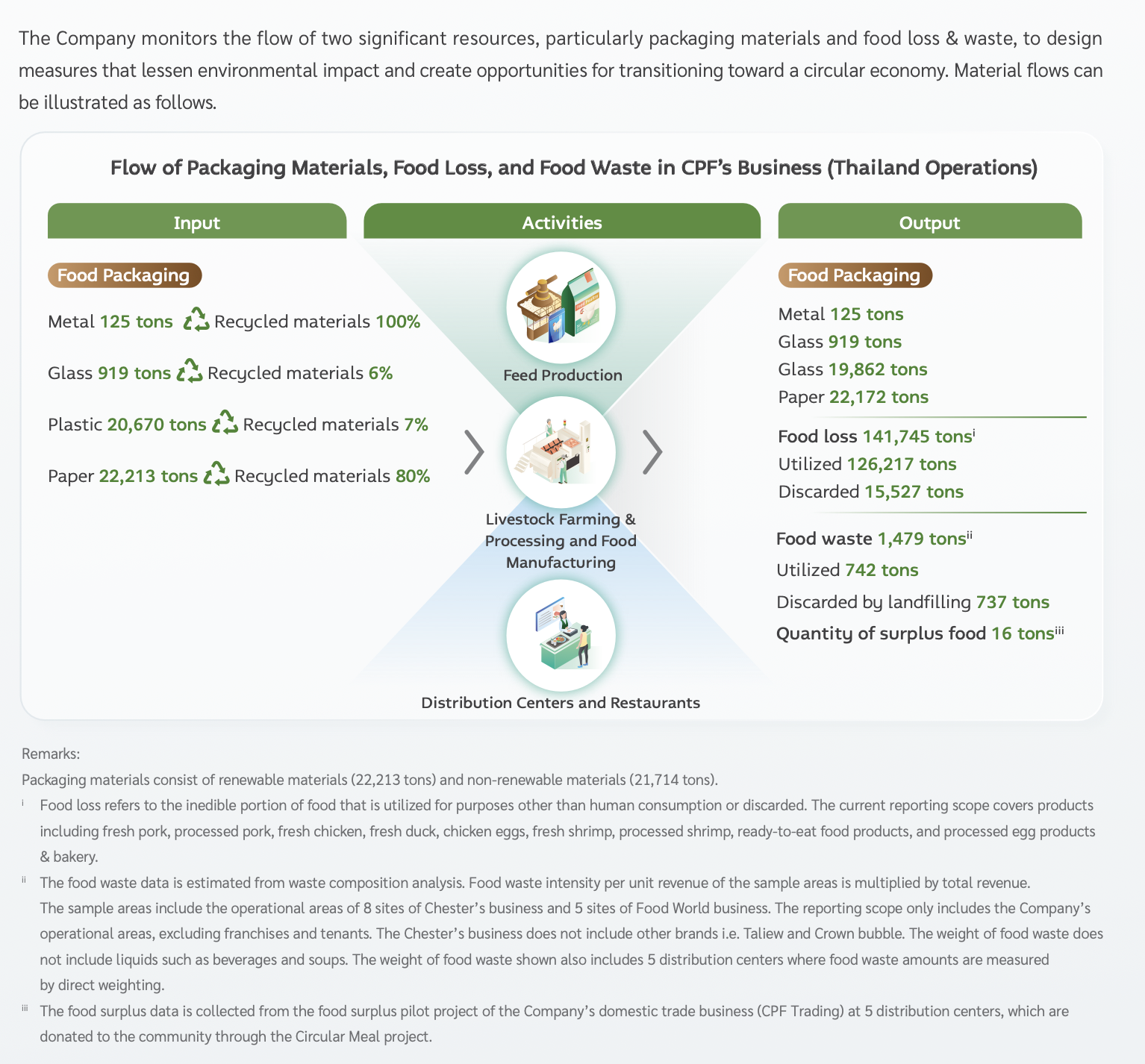

CPF recognizes the importance and strives to develop production processes throughout the value chain to reduce food loss and food waste. CPF also promotes utilization of waste according to the principles of circular economy, covering animal farming, food processing, distribution center and channels and restaurants. Further to this, CPF supports the United Nations’ Sustainable Development Goals (UN SDGs) on sustainable production and consumption. Therefore, CPF has formulated the Food Loss and Food Waste Policy with the following guidelines:

Consolidate data on food loss, surplus food and food waste in accordance with Food Loss & Waste Protocol

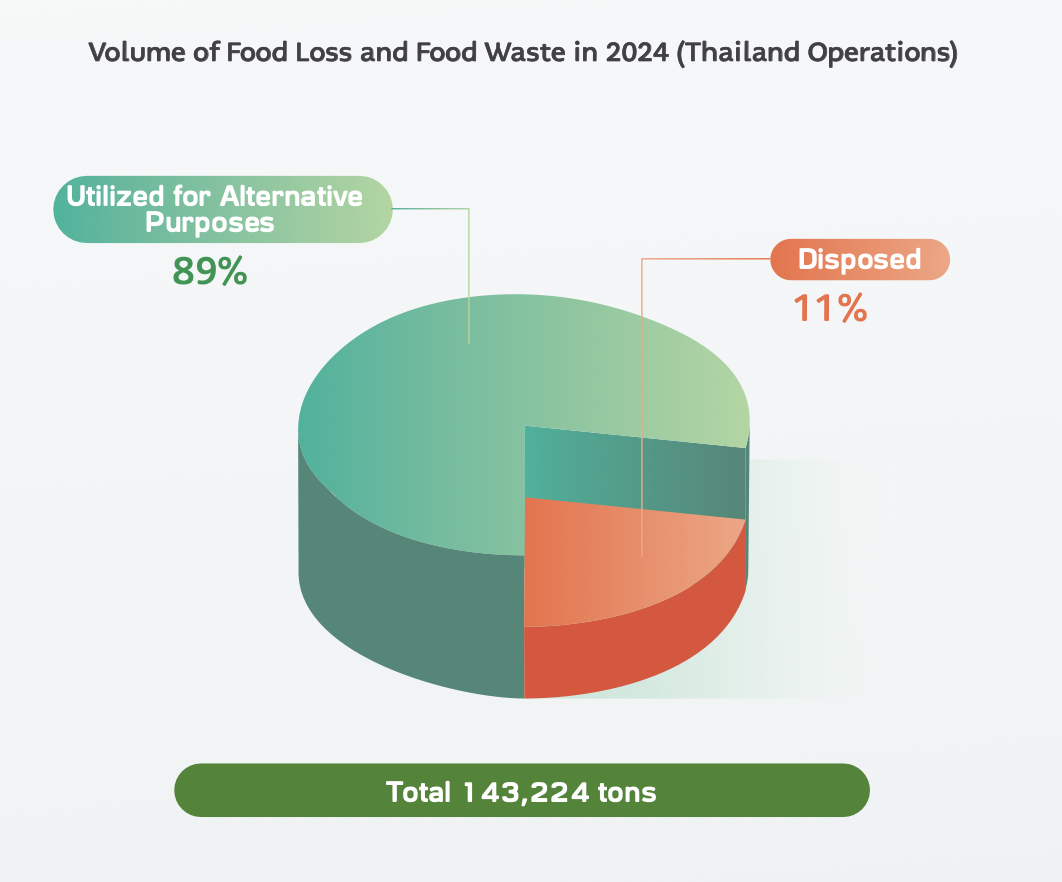

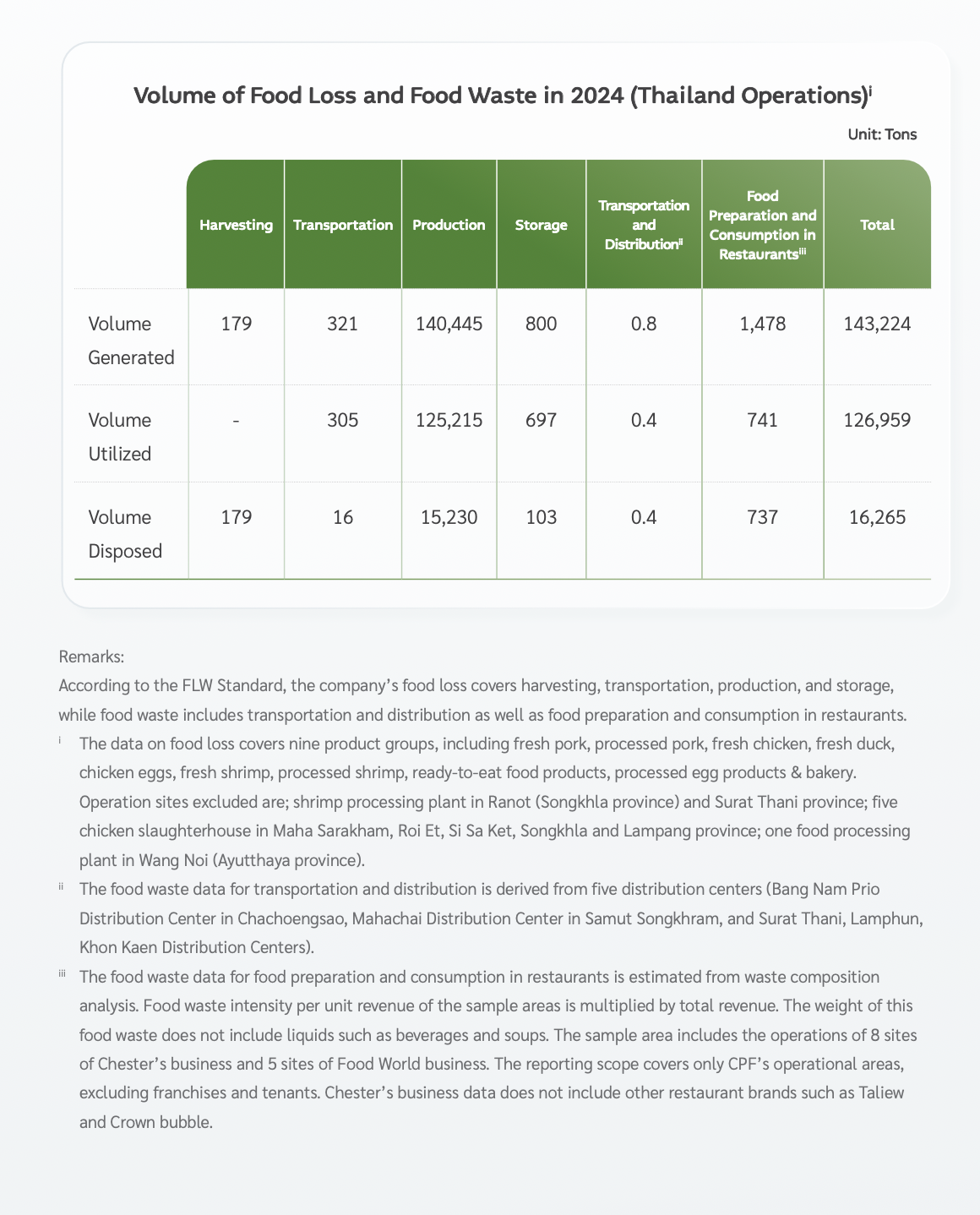

The Company has collected data on food loss in accordance with the data collection guidelines of the Food and Agriculture Organization (FAO) since 2020, focusing on quantity, quality, and economics, to assess food loss and identify reduction measures throughout the value chain. Currently, this covers our operations in pork, layer chicken, broiler chicken, duck, aquaculture, ready-to-eat food, and processed eggs and bakery. The Company collects and analyzes the volume of food loss in each activity throughout its value chain to identify hotspots of food loss, leading to the development of projects preventing and reducing food loss. For example, the Company has increased the efficiency of pork production by improving internal handling processes in slaughtering and butchering, such as trimming, transferring, storing, and selling.

Reducing Food Loss, Surplus Food and Food Waste from the Production Process

The management framework is as follows: